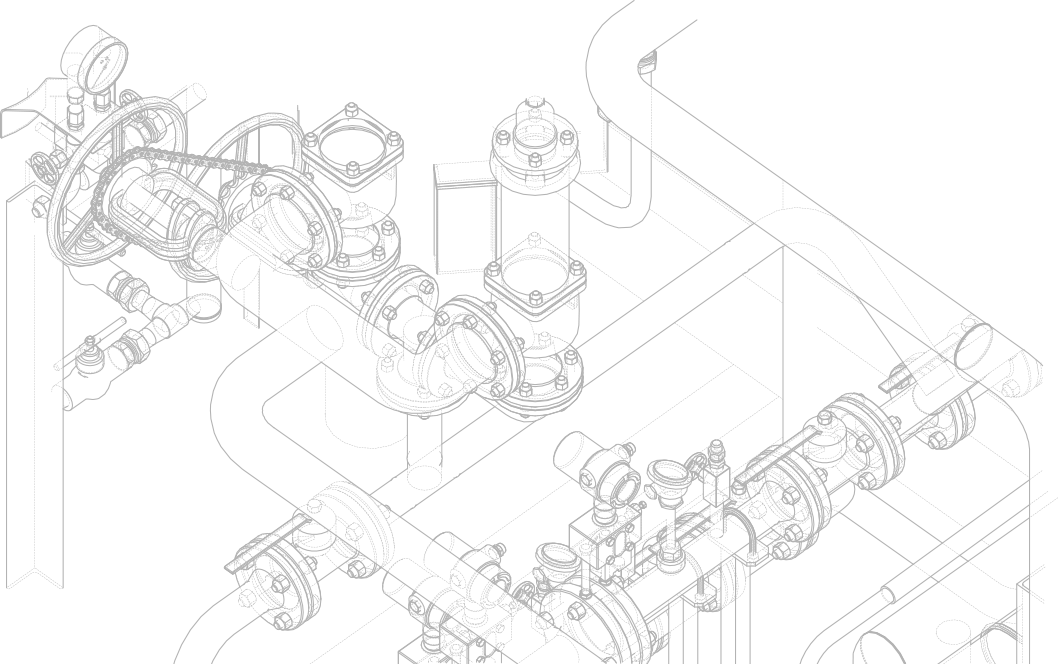

Piping Fabrication & Installation

Quality Fabrication Solutions

Both of our pipe fabrication facilities in St. Louis and Denver provide the efficiencies and quality we need on all our industrial, medical, and commercial projects.

We maintain the highest degree of quality throughout every steel fabrication project with our investment in cutting-edge equipment, the use of computer-aided design and drafting technology and the coordination of purchasing, scheduling and production.

There are many myths and incorrect information out there when it comes to metal fabrication and installation. Murphy Company continues to be one of the top fabrication companies because our staff is experienced and capable of providing you with the best piping services for your business. Contact us today to get started on your next project!

- Heat Treating

Altering the physical or chemical properties of a material. - DE Non-Destructive Examination

– Chart Recording testing

– High purity piping systems

– Hydrostatic testing

– Pneumatic testing - Pipe Racks

Laying out and assembling piping rack systems to improve field installation scheduling and efficiency. - Piping Skids

A combination of piping and piping equipment into self-supporting assemblies for ease of installation and flexible scheduling options. - Pipe Spools

Welded piping spool pieces using ASME Section IX qualified welders. - Pipe Supports

Structural steel piping supports and hangers to facilitate piping installation. - Prefabricated Assemblies

Assemblies of varying materials, types and systems to improve field installation time. - Versatile Welding

Automatic, semi-automatic and manual welding for carbon steel, nickel alloy, hastalloy, stainless steel, copper aluminum alloys, chrome, monel and other solid and clad weldable alloys.

- ANSI, API, AWS, AWWA, ASTM

- ASME Approved Quality Control Program

- Certificates of authorization to use ASME boiler and pressure vessel code stamps “PP”, “S”, “U” and “R”

- Abrasive Sawing

- Mechanical Sawing

- Oxy-fuel

- Plasma Arc

- “T” Drill Extrusions

- Flux Cored Arc Welding (FCAW)

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Shielded Metal Arc Welding (SMAW)

- Submerged Arc Welding (SAW)