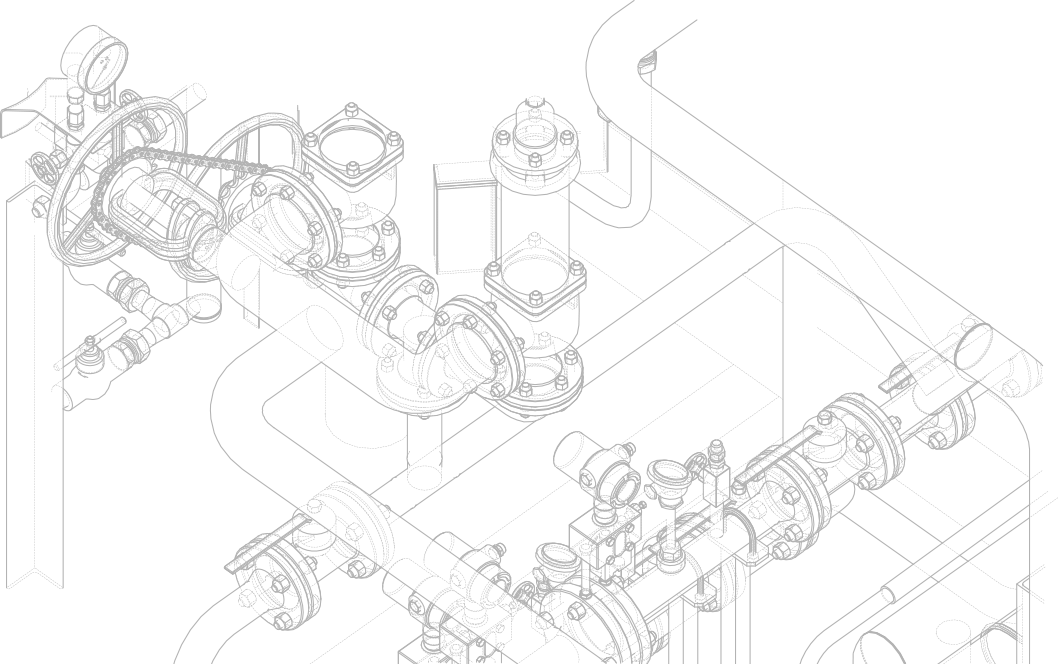

Sheet Metal Fabrication and Installation

Services & Solutions

Murphy Company continues to be a leader in the sheet metal arena of mechanical contracting. Our 50,000 square foot facility in St. Louis and our similar 18,000 square foot facility in Denver allow us to deliver full sheet metal fabrication services to all of our HVAC clients.

We have the flexibility to operate our fabrication facility on a multiple shift basis in order to meet aggressive schedules for our customers and to maximize their potential cost savings.

Both of our facilities are modern, automated and utilize top of the line equipment that represents the latest technology for sheet metal fabrication. Our teams of project professionals leverage the cost effectiveness of fabrication through our multiple innovative project delivery techniques and sheet metal fabrication equipment.

- A full range of equipment is available for TIG, MIG, stick and carbon arc welding.

- Automated coil line produces fully insulated, rectangular ductwork without handling.

- Flanged connections provide an air-tight seal in medium and high pressure systems, increasing efficiency and reducing contamination.

- Sheet metal fittings can be produced directly from computer produced drawings.

- Specialty industrial fabrication includes design, layout and fabrication of intricate ductwork, chutes, shapes and enclosures to your specific requirements.

- Two state-of-the-art plasma cutters and the latest heavy equipment including presses, rolls and shears enable the company to fabricate 26 ga. through 10 ga. stainless steel, aluminum, copper, black iron and galvanized steel.

- Button lock

- Pittsburgh and welded seams

- Slip and cap connections

- Soldered connections

- Standard angle connections

- TIG, MIG, stick and carbon arc welded connections

- Transverse duct flange (TDF)

- Computer driven plasma fitting cutter

- Fully automated 5 ft. insulated duct coil line

- Insulation application systems

- Power Brake

- Power, roto-die and hand brakes

- Power Shear – 10 ft., 10 ga. stainless

- Roll forming machines

- 26 ga. through 10 ga. galvanized, black iron and stainless

- Copper, aluminum, coated metals, prepainted metals, perforated metal and expanded metal

- HVAC

- Blowpipe

- Dust collection systems

- Fume removal systems

- Cleanrooms (Class 10,000 through 1)

- Operating Rooms

- 3-D computer aided drafting

- Computer design, estimation and fabrication

- NEBB certification

- NEMI contractor

- Thorough design/build capabilities utilizing

- an in-house professional engineering staff

- Paint shop/booth fabrication

- Sound level evaluation