Initially, this was an outdoor rink built in 1972 on land donated by the Affton Khoury League from what was originally a baseball field. Over the years the rink was enclosed, but water/ice build-up under the rink was heaving and causing uneven ice that now made smooth skating impossible. Also, the aging refrigeration system for the ice was outdated and in constant need of repairs. Time and lay-down space were two of the major challenges facing this project. The Affton Athletic Association wanted as little “down” time as possible due to upcoming league practices and the winter hockey season. Also, there was little to no laydown space on site for the massive amount of pipe and equipment to be installed under the 49-year-old rink.

Project owner’s requirements, including schedule, budget, MBE/WBE, safety, environmental

Affton Ice Rink is the primary rink for the Affton Americans Hockey Club and is home to more than 40 Affton Americans teams and several high school programs. The organization provides opportunities for kids of all ages and skill levels, from age 4 to a St. Louis Junior Blues program. So, it was essential that we complete the project before the December holidays so all the teams could resume playing and tournaments could take place. Also, every effort was made to value engineer the project to provide the most value for this not-for-profit organization’s investment.

Complexity or uniqueness of construction

How many companies can completely tear out a 200 ft. by 85 ft. regulation ice rink and replace it with acceptable and regulation tolerances within under two months? We feel privileged and honored to have the expertise and knowledgeable engineers and skilled workforce in our Fab Shop and on-site to achieve that goal.

Innovative use of manpower, equipment, materials and/or technology

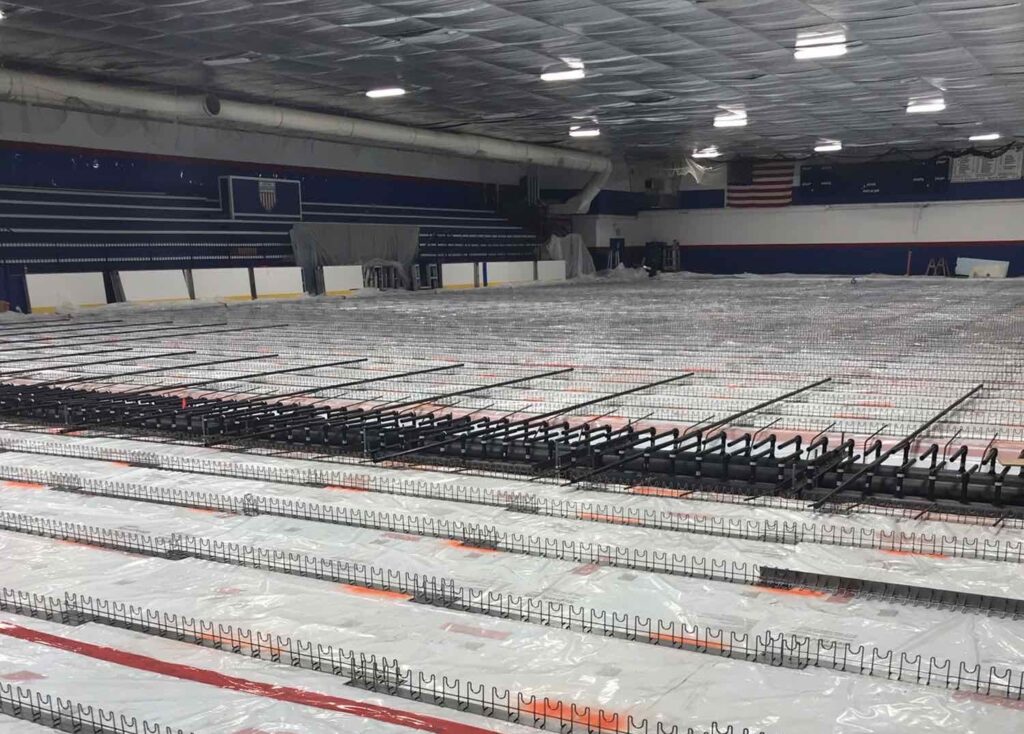

Murphy built on lessons learned on the St. Louis Blues ice rink to install 11 miles worth of pipe under the new Affton Athletic Association ice rink in a remarkably short two month-period. Murphy pre-fabricated header links and circuit piping, pre-fabricated U-bends and performed shop welds to speed installation, designing a unique spool system to coil up the 11 miles of pipe in 200-ft. lengths.

Solutions to special challenges

200-ft. lengths of the 1” pipe were spun up on the coils, U-bends prepared and welding performed in the Fab Shop, providing an extra measure of quality control. Then butt fusions (HDPE welds) were performed on site.

Job site safety – owner-mandated, contractor motivated

Murphy had no recordable incidences on this project, despite nearly 1200 hours and working in an extremely tight site with minimal laydown. Our foremen held daily meetings to review safety issues. Murphy’s skilled workers utilized Murphy’s proven Behavioral Based Safety protocols whereby each person looks out for the safety of coworkers.

Innovative and creative solutions to job-specific challenges

Kozeny-Wagner was responsible for the rink tear out and bringing the site up to grade. Murphy Company then worked with Vee-Jay on the subfloor grading systems. To achieve best accuracy, some of the floor was hand-leveled to a point. We assisted with scheduling so they didn’t have to shim the entire floor to achieve the necessary tolerance for distance from the top of the slab.

Effective project communications

Murphy used a push-pull Microsoft schedule to manage the project. Regular project team meetings and close coordination between our project manager, foreman, Fab Shop, GC and on-site rink manager kept things on track. During installation daily task and safety meetings took place.

Use of Technology and Innovation

Our Fabrication Shop created a unique large spool distribution system (like a sewing machine) to spool up 200-ft. lengths of 1” pipe. We then mounted the spools on a gantry, allowing us to pull circuits off spool, lay them onto the seats, and then on the ground, attaching the U-Bends. We installed more than 11 miles of 1” pipe using this method, which proved to work very efficiently and well!

How did you manage schedule?

The schedule was our main challenge with conceptual design and bidding beginning in July. It then took a yeoman’s effort and tight coordination to get all the equipment ordered. We used a Microsoft push-pull schedule to manage our work, installing the central plant after the floor work had been completed.

Surpassing quality expectations

On the Enterprise ice rink, we used a field surveyor to measure tolerances. At Affton, we used laser scans to ensure tolerances of subfloor elevations to the top of the slab. Hand-shimming, pre-fabrication shop control, and shop-inspected butt fusion welds all provided additional quality control to this project.

Workforce diversity (minority and female participation) and contractor/subcontractor diversity (MBE and WBE participation)

Murphy supports and encourages a diverse and inclusive workforce in its Fab Shops as well as on all job sites. Murphy stringently enforces all EEOC requirements in its recruitment and hiring. We also regularly work with MBE/WBE companies as subcontractors/suppliers. There were not any set requirements for this project.

Budget adherence and value engineering

The total cost of this project was $6 million and Murphy was successful in completing our portion of the project for $1.4 million. Murphy Company provided the “value-add” of an excellent working relationship with Kozeny-Wagner, the general contractor; Vee-Jay Cement, with which we worked hand-in-hand on the sub-soil and rink leveling; and our experience and strong working partnership with M & M Refrigeration, which designed the new system. Our experience with the Enterprise Center and the St. Louis Blues paid off handsomely for the Affton Athletic Association. By pre-fabricating the piping and creating the large coil delivery system, we were able to save the owner costs and also solve the “Lay-down” issues.

Innovative reuse of building waste or materials

Although the building is quite old and not well insulated, Murphy Company provided an energy efficient refrigeration system – a definite improvement in compressor technology along with a controls system to manage interface of the ice. The Affton Athletic Association is aware that it still needs to address air systems quality and efficiency.

Innovative or creative actions that benefitted the community

Because of Murphy Company’s experience with the Enterprise Center’s St. Louis Blues ice rink and our ability to pre-fabricate and accelerate the schedule, we were able to complete the construction phase in a record time of two months so the winter leagues could start on time.

Other achievements (i.e., promoting cooperation, workforce recruitment efforts, streamlining construction process, etc.)

Close coordination between Murphy Company and Vee-Jay was very helpful in streamlining efforts and achieving the necessary tolerances for the new ice. Rather than “working in silo’s”, we coordinated our efforts to achieve regulation tolerances between the floor and the surface of the ice. COVID protocols during this project, including regular testing and social distancing, also called for great cooperation among our workforce.